Introduction

Machinery forms the backbone of the oil and gas industry, powering critical processes across exploration, production, refining, and transportation. From drilling rigs and compressors to pipelines and turbines, these machines operate under extreme conditions to ensure seamless and efficient operations. Their reliability is directly tied to the productivity, safety, and profitability of oil and gas companies, making maintenance and performance optimization essential.

Efficient turbine maintenance is a cornerstone of uninterrupted oil and gas production. Turbines play a critical role in key operations such as power generation, gas compression, and pumping, often operating in challenging environments with high temperatures, pressures, and loads. Ensuring their reliability is paramount not only for maintaining operational efficiency but also for avoiding costly downtimes and mitigating safety risks.

The Challenge: Preventing Downtime in Tough Conditions

In oil and gas production, turbines operate under extreme conditions. Sensor data such as temperature, pressure, vibration, and rotational speed provide crucial insights into their health. Traditionally, maintenance was either reactive (fixing issues after failure) or time-based (scheduled regardless of the turbine’s condition). Both methods lead to inefficiencies, unexpected downtime, and higher operational costs.

To address these challenges, predictive maintenance emerges as a game-changer. By leveraging advanced analytics and machine learning models, predictive maintenance uses real-time sensor data to anticipate potential failures before they occur. This approach ensures timely interventions, minimizes downtime, and optimizes maintenance schedules based on the actual condition of the equipment, leading to improved operational efficiency and reduced costs.

What is Predictive Maintenance?

Predictive maintenance, powered by advanced data analytics and machine learning, is revolutionizing how we approach turbine care. By leveraging real-time sensor data—tracking variables such as temperature, pressure, vibration, and rotational speed—predictive maintenance software can anticipate issues before they arise, enabling a shift from reactive to proactive maintenance. This transformative approach helps maximize turbine uptime, optimize resource utilization, and enhance overall safety in oil and gas operations.

The Benefits of Predictive Maintenance

Improves Operational Efficiency

By predicting and addressing issues before they escalate, predictive maintenance ensures that turbines run smoothly, maximizing productivity and optimizing energy use.

Extends Asset Lifespan

Regular, informed maintenance based on real-time data helps maintain turbine components in peak condition, preventing wear and tear and extending the equipment’s useful life.

Reduces Unplanned Downtime

By identifying potential failures in advance, predictive maintenance minimizes the risk of sudden breakdowns, leading to more consistent operation and fewer interruptions.

Lower Operational Costs

Predictive maintenance reduces emergency repair expenses and minimizes resource allocation during unplanned failures, leading to significant cost savings.

Data-Driven Decision Making

Predictive maintenance leverages detailed analytics and sensor data to inform maintenance strategies, empowering teams to make more precise, evidence-based decisions.

Case Study: Transforming Turbine Maintenance in Oil and Gas Using Predictive Analytics

A leading oil and gas company operating in offshore and onshore environments faced frequent turbine downtimes. These turbines were critical for powering operations, gas compression, and pumping, but their maintenance approach relied on a combination of reactive and time-based methods, resulting in unexpected failures, increased costs, and reduced operational efficiency.

Acuvate, addressed this challenge by leveraging AI-powered predictive maintenance, streamlining the maintenance process, and minimizing manual dependencies. By utilizing advanced analytics and machine learning, Acuvate helped the client transition from a reactive and time-based maintenance approach to a more proactive and efficient predictive maintenance model. This solution provided real-time insights into turbine health and allowed for timely interventions, thus reducing downtime and maintenance costs while enhancing operational reliability.

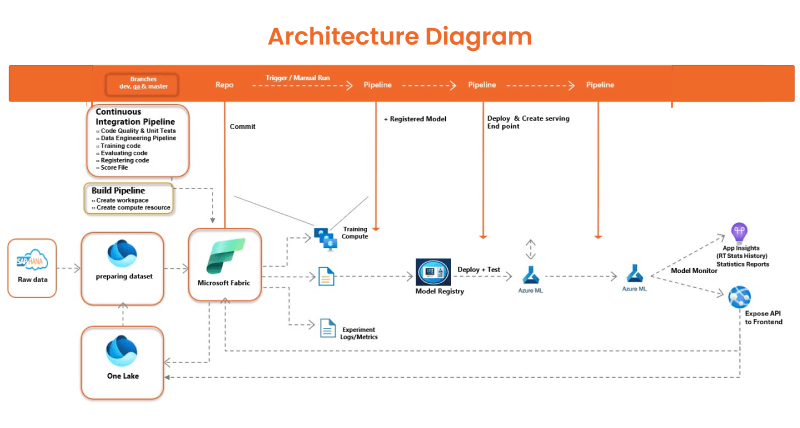

Architecture: A Data-Driven Approach

To tackle this challenge, Acuvate designed a streamlined Azure data architecture that seamlessly integrates data ingestion, preprocessing, model training, and deployment. Here’s how the flow works:

The solution was designed using a cloud-based architecture combining Microsoft Fabric, Azure ML, and Power BI.

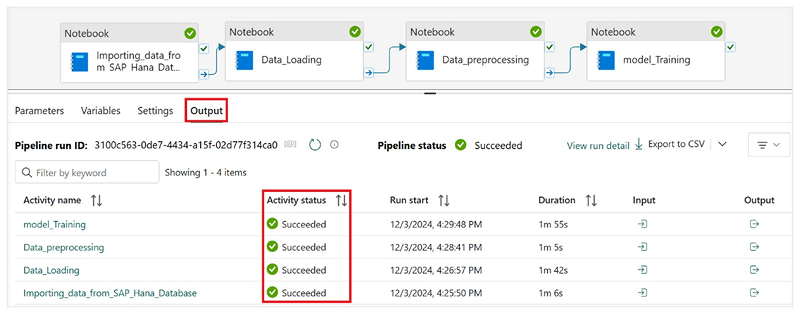

End-to-End Automation Using Microsoft Fabric Pipelines

From data ingestion to model training, every step within Microsoft Fabric was seamlessly automated using its powerful pipelines. These pipelines handle tasks such as extracting raw data from SAP HANA, preprocessing it to clean and transform inputs, and training machine learning models directly within Microsoft Fabric. The trained models are then exported for deployment in Azure ML.

By leveraging Microsoft Fabric pipelines, the system ensures consistency in data processing, minimizes the risk of human error, and reduces manual effort. This automation accelerates the transition from raw data to actionable insights, enabling real-time predictions and more efficient turbine maintenance planning.

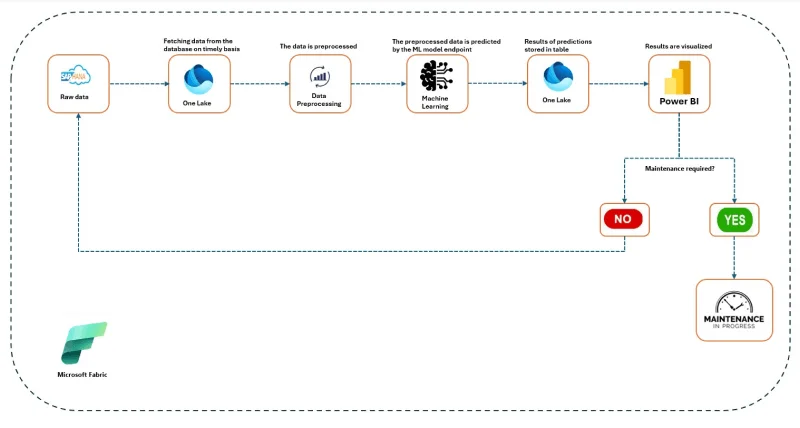

Process Flow

For an enterprise, integrating predictive maintenance into daily operations begins with data collection and ends with actionable insights. Here’s how the solution works in real time:

- Data Collection

Sensor data—such as temperature, pressure, vibration, and rotational speed—is captured from the client’s turbines and stored in an SAP HANA database. This data is extracted on an hourly basis, ensuring near real-time visibility into turbine performance.

- Data Integration and Storage

The hourly data is ingested into Microsoft Fabric One Lake, where it is organized and stored in structured tables. This centralized platform enables efficient preprocessing and analysis.

- Preprocessing

Through Microsoft Fabric pipelines, the ingested data is preprocessed to address missing values, detect anomalies, normalize features, and engineer new metrics. The clean data is stored on a separate table for analysis.

- Running Predictions

The processed data is sent to the deployed Azure ML model endpoint, which evaluates the sensor readings to determine whether maintenance is required. The prediction results are stored in another results table in Microsoft Fabric.

- Real-Time Visualization

Using Power BI dashboards, the prediction results are visualized, providing the maintenance team with clear, actionable insights. The dashboard highlights turbines requiring maintenance, enabling timely action to prevent potential failures.

- Actionable Maintenance Decisions

Based on the Power BI visualizations, the maintenance team can schedule repairs or replacements during planned downtime, avoiding disruptions and ensuring operational efficiency.

This workflow demonstrates how sensor data seamlessly flows through the system—from SAP HANA to Microsoft Fabric to Power BI—enabling enterprises to make proactive, data-driven maintenance decisions.

Technical Highlights of the Flow Flow

- Data Ingestion

Data flows seamlessly from SAP HANA into Microsoft Fabric One Lake, providing centralized and scalable storage as the foundation for further processing.

- Preprocessing and Training

Microsoft Fabric pipelines play a pivotal role, handling data transformation and enabling efficient machine learning model training directly within the platform.

- Model Deployment

The trained models are exported to Azure ML, where they are registered and deployed as real-time prediction endpoints for continuous monitoring.

- Visualization

Power BI dashboards, integrated with Azure Data Fabric, provide actionable insights derived from the predictions, empowering stakeholders to make data-driven decisions.

Business Impact

The predictive maintenance solution delivered significant business benefits:

- Reduction in Downtime

Early detection of potential issues drastically reduced unplanned outages

- Optimization in Maintenance

Maintenance activities were aligned with actual turbine conditions, reducing unnecessary servicing.

- Cost Savings

Lower operational costs due to minimized emergency repairs and more efficient resource allocation.

- Improved Safety

Predictive maintenance reduced the risk of catastrophic turbine failures, enhancing safety standards.

Use Case in Action: A Day in the Life of Predictive Maintenance

When a turbine shows subtle fluctuations in vibration and rotational speed. These variations are captured by sensors and relayed to the predictive maintenance system in real-time. The trained machine learning model processes the data, identifying patterns that indicate potential issues.

The predictive model triggers an alert, sending detailed insights to the maintenance team, including severity, estimated time to failure, and recommended actions. The team receives this information through a user-friendly dashboard, enabling quick and informed decision-making.

Thanks to this approach, the team schedules a maintenance session during planned downtime, preventing an unexpected failure that could have led to costly repairs and production stoppage. The faulty parts are replaced without major disruption, ensuring the turbine continues to operate efficiently. This timely intervention helps avoid downtime, reduces repair costs, and contributes to overall operational safety and reliability.

Future Scope: Revolutionizing Maintenance in Oil and Gas

Advancements in Technology

Continuous improvements in sensor technology, machine learning, and data analytics will enhance predictive maintenance systems, providing more accurate predictions and smarter automation.

Extended Benefits

Predictive maintenance will further improve operational efficiency, extend equipment lifespan, and help achieve sustainability goals in the oil and gas sector.

Enhanced Safety and Compliance

As predictive maintenance evolves, it will support better safety protocols, reduce environmental impact, and help meet regulatory sustainability standards.

Integration with Emerging Technologies:

Predictive maintenance will integrate with AI, edge computing, and blockchain, enabling more intelligent, transparent, and cost-effective operations.

Long-Term Impact

The continued adoption of predictive maintenance will revolutionize turbine and equipment management, making operations more resilient, adaptive, and environmentally responsible.

Conclusion

Machinery maintenance in oil and gas production is entering a new era. With predictive analytics and machine learning, we can transform raw sensor data from various equipment into actionable insights, enabling timely and efficient maintenance. This approach ensures reliability, reduces downtime and costs, and enhances safety across operations—a win for businesses, the environment, and long-term sustainability.